Filling Machine Revamping and Re-tooling

Filling Machine Revamping and Re-tooling

This project consisted of revamping equipment designed for filling, capping and labeling of glass vials in a clean room.

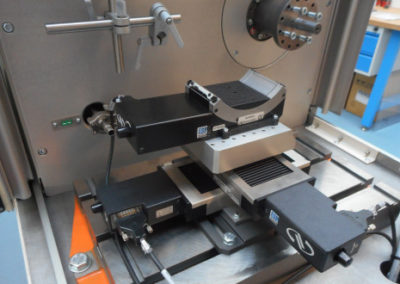

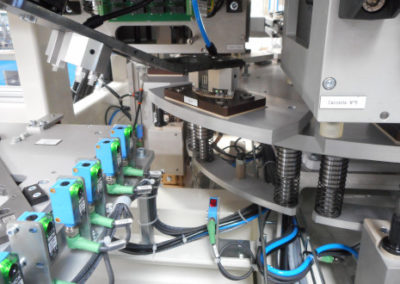

MGA Technologies modified an existing piece of German-built CAM-controlled equipment to allow the production of 4 ml and 8 ml bottles filled with liquid or lyophilised product. The automation of this equipment was completely replaced.

The operation consisted of replacing the old sensors with new ones, completely re-wiring the machine and adding a new cabinet with integrated Schneider PLC and HMI.

Rails, trays and other change parts have been made to measure. Automatic distribution of plastics plugs with vibrating bowls and rails, a pick system and pre-screwing were added. A Weber electric screwdriver allows tightening the caps to the desired torque. The mechanical drive was also modified by changing the profile of some CAMs. A Herma labeler was integrated at the end of the line to identify the bottles by distributing labels, printed, verified by camera and affixed to the side of the bottle.

Technical specifications:

- PLC and HMI: SCHNEIDER M340&Magelis

- Bowl and vibrating rail: ROLAND BAILLY

- Electric screwdriver: WEBER

- Automatic labeling: HERMA

Do You Have a Similar Need?

Contact our sales team to get a personalized quote for a custom-made project.

They Trust Us

Follow the News of MGA Technologies

Subscribe to the newsletter of MGA Technologies

Contact Us

We are available from 8am to 6pm (UTC-4), Monday to Friday.