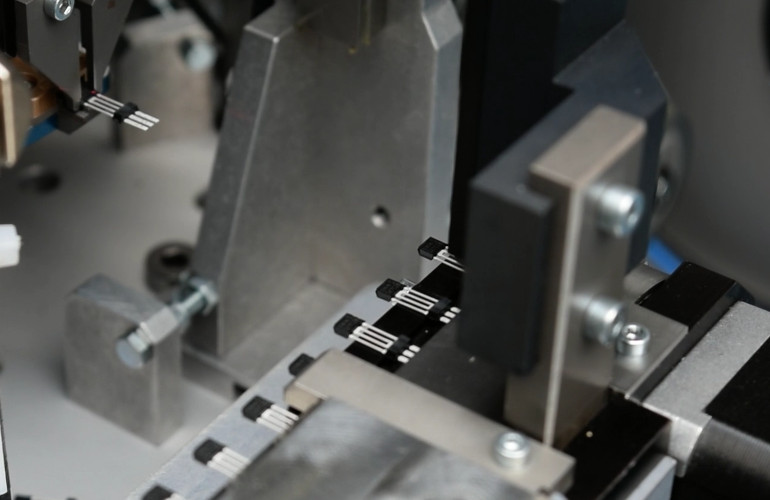

Hall Sensor Cutting and Forming Equipment

- Cutting and bending equipment are modular and specially designed for sensors preparation prior to welding.

- Typical application include Hall effect sensors widely used in the industry for position detection.

- Feeding: cardboard strip, blister

- Modular bending: up to 3 positions

- Bending: 0° to 90 °

- Calibrated cutting of the components pins

- 100 % electrical

- Compact (H: 640mm, W: 625mm, D: 600mm)

- Manual Loading / Unloading

- 900 cells per hour

- Electrical supply with a simple 110V to 220V

- Noise level < 70 dB

- Bending accuracy < 2°

- Cutting accuracy +- 0.1 mm

- Modular, evolving and interchangeable tools

- Magnetic or non-magnetic cells with 3 to 5 pins

- Shuttle, Buckets or Simple belt conveyor

- Optical reader for references identification

- Handshaking with existing machine

- Can be integrated in an automatic machine

Functioning of the MGA Hall-effect Cutting & Bending Equipment

Get a Free Quote with no Obligation

Contact our commercial team to get a customized quote for a MGA hall-effect sensor cutting & Bending equipment.