Component Assembly Robots

Component Assembly Robots

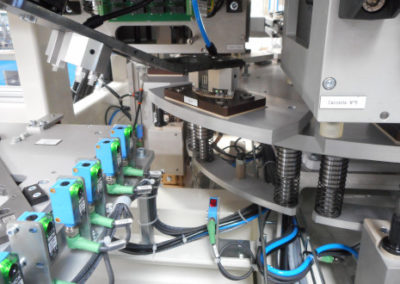

This project consisted of a component assembly robot integrated in semi-automatic cell made of a flat top conveyor that sequentially assembles several components.

The principle of this cell is to line up an operator and to manage production rates with a buffer on the conveyor. Components are distributed manually by the operator on dedicated plates ensuring reference positioning.

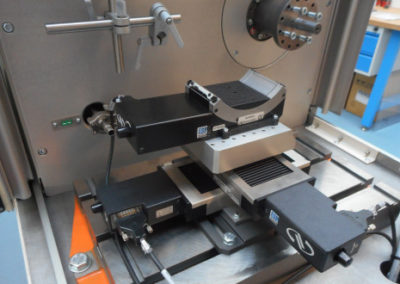

The component assembly robot then takes over by assembling the parts in a repeatable manner, ensuring the perfect quality of the assembly. Several technologies have been integrated in this installation, including vibrating bowl distribution, screwing and press fitting.

In the final station, the parts are 100% controlled with airtightness system and marked before being presented back to the operator.

Technical characteristics:

Do You Have a Similar Need?

Contact our sales team to get a personalized quote for a custom-made project.

They Trust Us

Follow the News of MGA Technologies

Subscribe to the newsletter of MGA Technologies

Contact Us

We are available from 8am to 6pm (UTC-4), Monday to Friday.