Impact of the new GMP Annex 1: the Challenges Facing the French Pharmaceutical Ïndustry

Annex 1 of GMP has been in force since 1971. An update was carried out in 2022 to better interpret certain points and to avoid ambiguities. All the sectors concerned must comply with the new version of Annex 1 before 25 August 2023, the date from which it comes into force. The impact of the new GMP Annex 1 will be greater than that of previous versions, due to the new requirements imposed.

The pandemic crisis has had a particular impact on the pharmaceutical sector. France wants to be at the top of the league table of the most innovative pharmaceutical industries. To achieve this objective, the industry must face up to a number of challenges.

Empowering Every Employee

At a time when the market is globalised, controlling health and economic risks and anticipating and managing crises are becoming increasingly important. To become competitive, the pharmaceutical industries must face up to the various challenges that could lead to non-quality and mass recalls of medicines. They must also ensure good coordination both internally (between all functions) and externally (with all participants in the product chain).

Among the good coordination required internally, industries must give priority to the autonomy and empowerment of each employee, as well as the sharing of current standards (GMP, BP, ISO, etc.). The aim is to anticipate and optimise the management of potential health risks.

Optimising Team skills

In addition to empowering individual employees, companies must also optimise the skills of their workforce to ensure that processes comply with GMPs and applicable standards, and to guarantee product quality. To achieve this, they need to surround themselves with employees with specific skills in purification, analytical development, risk anticipation and management, process engineering and quality control. Pharmaceutical companies also need skills and expertise in process digitalisation and IT.

All these technical skills are essential to quality control. They are used to identify regulatory non-conformities. It is the responsibility of the qualification or validation manager to ensure compliance with standards and guidelines (GMP, BP, ISO, etc.). He or she is also the guarantor of the skills of the teams as part of a quality management system.

The New Requirements of the Updated Annex

As with previous versions, annex 1 of the GMP updated in 2022 will affect the manufacture of sterile medicinal products manufactured and imported into the European Union. Good Manufacturing Practices require that manufacturing processes take place in controlled, sterile environments to guarantee product quality and protect patients. Annex 1 provides more details on strategic control and quality measurement. It also aligns manufacturing principles more closely with those of the Food and Drug Administration (FDA), the Pharmaceutical Inspection Cooperation Scheme (PIC/S) and the World Health Organisation (WHO).

The new GMP Annex 1 involves a number of changes and requirements:

Quality Risk Management (QRM)

The manufacture and use of pharmaceutical products are always subject to a certain number of risks. The impact of the new GMP Annex 1 is to maintain the quality of medicinal products throughout their entire life cycle, so that their important characteristics are identical to those predicted during clinical studies. Effective risk management ensures product quality. In the event of a quality problem, it also helps to optimise the decision-making process. The new Annex 1 of the European GMP places emphasis on the implementation of effective CCS (Contamination Control Strategies) for cleanrooms and environmentally controlled areas, in order to prevent cross-contamination and maintain optimal conditions for pharmaceutical production. Contamination control strategies provide detailed guidance on requirements for facility design, cleaning and disinfection procedures, air monitoring, staff training and risk management, with the aim of minimising potential sources of contamination.

CCS are essential for preventing contamination in pharmaceutical production environments, ensuring product quality and maintaining patient confidence. They play a key role in compliance with European GMPs and promote innovation and continuous improvement in the pharmaceutical industry.

Taking account of new technologies and innovative processes

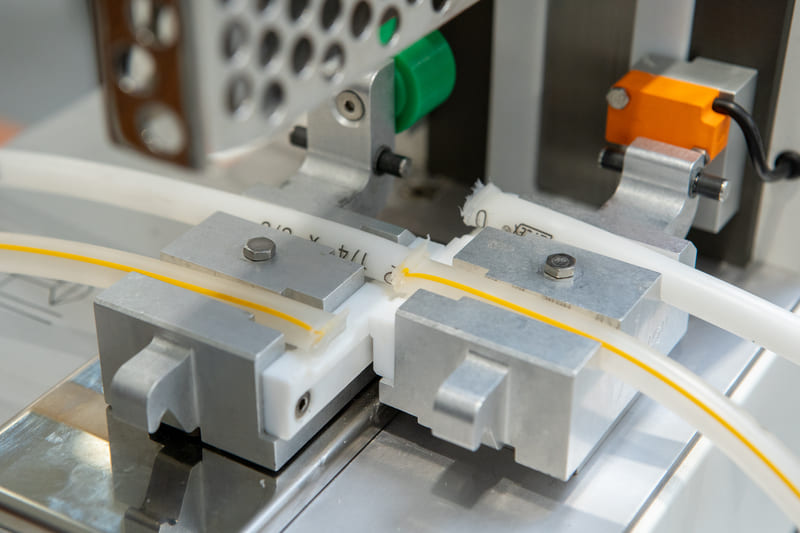

Annex 1 of the GMP emphasises the automation and robotisation of pharmaceutical manufacturing processes. It requires automated solutions to be combined with barrier isolator technology (also known as RABS, for Restricted Access Barrier System) to protect active ingredients and medicinal products from contaminants. The integration of robotics in the pharmaceutical industry should help to optimise productivity, as well as containment and sterility conditions during processes.

Other Requirements of the New GMP Annex 1

Annex 1 of the GMP is also being revised in August 2022, because the authorities want to align the standards and harmonise them with the FDA’s guidelines on sterile pharmaceutical products. The annex also includes warning letters and GMP non-compliance statements for sterile processes.

MGA Technologies: your Partner in Quality Risk Management

Implementing quality risk management procedures in line with the requirements of the GMP Annex 1 update is not always easy. Fortunately, pharmaceutical companies can call on the support of specialists in the field, such as MGA Technologies. We specialise in the design, manufacture and integration of robotic solutions for a variety of sectors, including pharmaceuticals.

With us, you can be sure of benefiting from our technical expertise in implementing quality risk assessment procedures. We can also analyse the level of risk in your production line and provide the most appropriate level of effort, formalisation and documentation of the risk management process.

If you have any questions, please do not hesitate to contact our technical experts.