Industry 4.0: The Future Of Your Production Tool

The migration to Industry 4.0 allows a company to benefit from technological advances and technical progress in work organisation. The interconnected factory 4.0 emphasises the interaction between operators, employees and products. According to forecasts, 600,000 direct and indirect jobs will be affected by Industry 4.0 in France by 2025. It will also create up to 60 billion in added value.

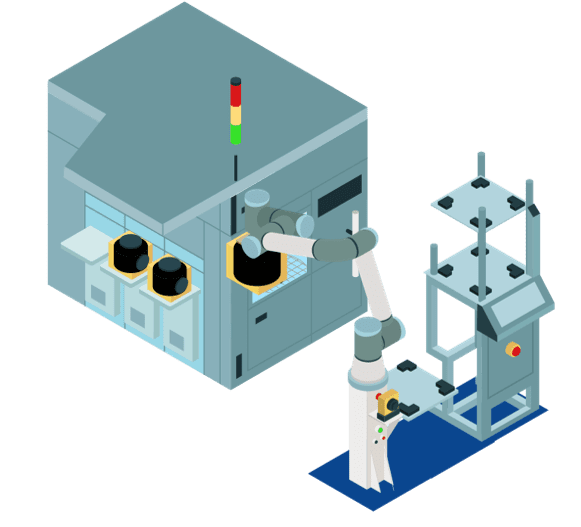

New technological advances enable industries to meet the ever-increasing needs of their customers in terms of product price, quality and quantity. They must now be able to increase their productivity, ensure the quality of their products and develop customised products.

With Factory 4.0, you will benefit from

- Better operational efficiency, thanks to the modernisation of your production tool and maintenance operations;

- Increased production and reduced production costs by automating repetitive and low value-added tasks;

- Optimisation of product quality, due to the reduction of human errors.

For these and many other reasons, Industry 4.0 appears to be the future of production tools. Despite its many advantages, however, this innovative solution is not without risks.

Managing The Risks Of Industry 4.0

There are many risks that need to be analysed and controlled in Factory 4.0:

- Human risks resulting from the implementation of new production tools;

- Technical risks corresponding to the deployment of new technologies;

- Organisational risks, caused by the use of new technologies;

- Digital risks: the company may become a prime target for various forms of attack such as ransomware, phishing, denial of service attacks, etc.

To control the risks of Industry 4.0 and to take advantage of the transformation to Industry 4.0, it is useful to establish a clear and precise roadmap:

- Technical control of equipment: make sure you control the safety and performance of new equipment;

- Include the human factor in the migration: consult staff, train them to use the new tools correctly;

- Control the consequences on the organisation, or more specifically on maintenance, workstations, procurement, etc;

- Prevention of risks related to the use of new equipment: assessment and prevention of MSD and psychosocial risks.

Working With Mga Technologies For The Transition To Industry 4.0

Are you planning to migrate to Factory 4.0 to optimise your productivity, reduce your production costs and increase your profitability? Then make MGA Technologies your reference partner to realise your project. We are a French company, internationally recognised since 1980 for the design, manufacture and integration of customised machines and turnkey equipment for industry. We are aware that controlling the risks of Industry 4.0 is one of the major factors guaranteeing the success of your project. By calling on us, you benefit from better support for the integration of new equipment, the control of its use and the control of its effects on the organisation and on your employees. Thanks to the expertise of the MGA Technologies team, your decision to become a 4.0 factory will only benefit you and your employees.

So, whatever your sector of activity and your business needs, choose MGA Technologies to control the risks of Industry 4.0. Contact us for more information on our services and products.